1060 aluminium coiled buis

ASTM B210 1060 Aluminium coil buis foar Evaporator

1060 aluminium alloy is in aluminium-basearre alloy yn 'e "kommersjeel suvere" smeid famylje (1000 of 1xxx rige).It is yn prinsipe tige ferlykber mei 1050 aluminium alloy, mei it ferskil komt del nei 0,1% aluminium troch gewicht.

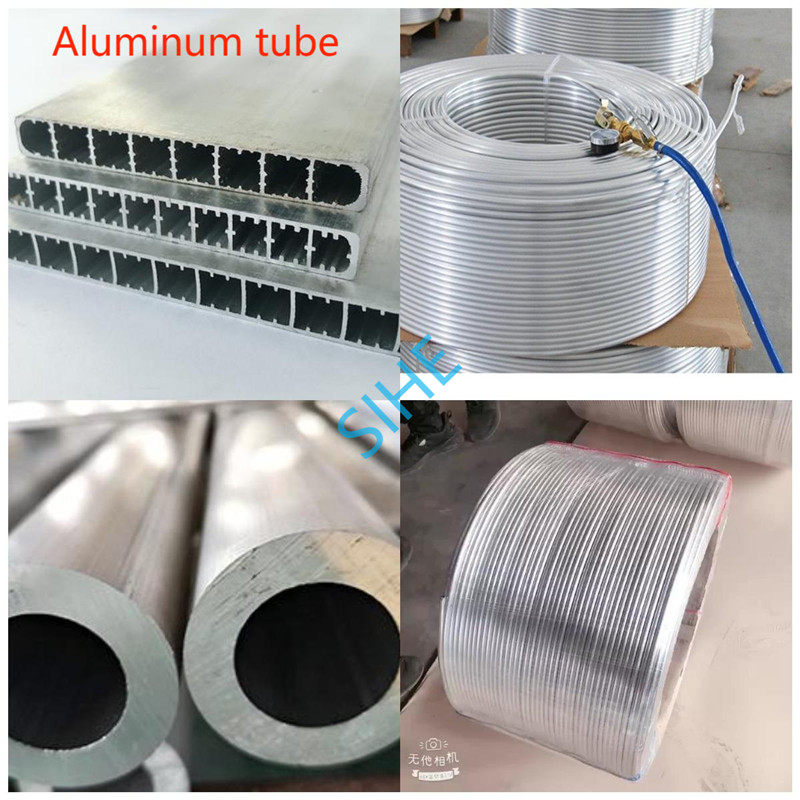

Aluminium buis foar de HVAC & R yndustry.it oerflak fan 'e coiled buis is glêd, gjin poaren, gjin wear, en stikstof wurdt hanthavene.aluminium buizen binne benammen geskikt foar lange produksje rint foar yndustriële tapassingen.Benammen wurde brûkt op de airconditioning, friezer, kuolkast, Condenser, intercooler, evaporator, waarme wyn beweging, airconditioning pipeline, auto radiator, ensfh

1 .Alloy: ASTM B241 1050/1060/1070

2. Temperatuer: O/H12/H14/H16/H22/H24/H26/H112/F

3. Dikte: 0.7mm--1.5mm

4. Diameter: neffens klant easken

5. Tolerânsje: +/- 0,05mm

6. Applikaasje: airconditioning, kuolkast, roll-bond evaporator, waarmte Exchanger, oven gas, condenser, en intercooler ensafuorthinne.

7. Pakket: Houten pallets of kisten geskikt foar lange-ôfstân seeferfier, it is kin oanpast wurde troch kliïnten.

Spesifikaasjes

| A1050 Aluminium gemyske gearstalling | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Oaren |

| 99,5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium gemyske gearstalling | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Oaren |

| 99,6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium gemyske gearstalling | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Oaren |

| 99,7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| Fysike eigendom fan 1050 1060 1070 aluminium buis piip | ||||||

| Legearing | Temper | dikte fan de muorre | Keamertemperatuer Test Resultaat | |||

| Spanning Strength / MPa | Yield Strength / MPa | Ferlinging/% | ||||

| A50 mm | A | |||||

| Net minder as | ||||||

| 1050 | O,H111 | Alle | 60 ~ 100 | 20 | 25 | 23 |

| H112 | Alle | 60 | 20 | 25 | 23 | |

| F | Alle | - | - | - | - | |

| 1060 | O | Alle | 60 ~ 95 | 15 | 25 | 22 |

| H112 | Alle | 60 | - | 25 | 22 | |

| 1070 | O | Alle | 60 ~ 95 | - | 25 | 22 |

| H112 | Alle | 60 | 20 | 25 | 22 | |

quanlity garânsje

1) oerflak uterlik: plat skjin oerflak gjin gehiel, kras, oalje smoarch of oksidaasje.

2) cutting edge: nette cutting edge gjin burrs.

3) Kwaliteit doel: de earste produkt ynspeksje kwalifisearre taryf is 98%. klanttefredenheid troch 95%. Materiaal: A1050, A1060, A1070, A3003, ensafuorthinne.

| A1050 Aluminium gemyske gearstalling | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Oaren |

| 99,5~100 | 0~0.25 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.40 | 0~0.03 |

| A1060 Aluminium gemyske gearstalling | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Oaren |

| 99,6-100 | 0~0.25 | 0~0.05 | 0~0.03 | 0~0.05 | 0~0.03 | 0~0.03 | / | 0~0.35 | |

| A1070 Aluminium Chemical Composition | |||||||||

| Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe | Oaren |

| 99,7~100 | 0~0.2 | 0~0.04 | 0~0.03 | 0~0.04 | 0~0.03 | 0~0.03 | 0~0.05 | 0~0.25 | |

| A3003 Aluminium gemyske gearstalling | |||||||

| Al | Si | Cu | Zn | Mn | Fe | Oare Single | |

| oaren | 0~0.6 | 0.05~0.20 | 0~0.1 | 1.0~1.5 | 0~0.70 | 0~0.05 | |

| Legearing | Temper | Spesifikaasje | |||

| Dikte (mm) | Diameter (mm) | Treksterkte | Hurdens | ||

| 7075 7005 (buis) | T5, T6, T9 | >0.5 | 5,0-80 | >310 Mpa | >140 |

| 6061 6063 (profilen) | t5,t6 | >1.6 | 10-180 | >572 Mpa | HB90-110 |

| Lengte: < 6 meter | |||||

| TEMPER | DIKKE (mm) | TENSILE STERKTE | ELONGATION% | Standert |

| T5 | 0,4-5 | 60-100 | ≥ 20 | GB/T3190-1996 |

Aluminium produkt